Automation Control

Automation Control was founded back a decade ago and provides Engineering Services, Equipment, Filtration, Regulation, Metering and Odorization stations for the natural gas industry. With a capacity to innovate and a team of experienced technicians we offer customized products and solutions for natural gas industry.

Our team of highly qualified professionals provide a one stop destination for a complete solution to the customers right from inception to until start-up of the stations. All our products and solutions are offered to meet ISO certification and complying to international standards like- ASME, API, AGA, ISO, ABSA

Engineering

Our team of qualified engineers design & develop according to the specific requirements of each project to offer an optimum technical & economical solution. With its crew of skilled & experienced professionals, our capabilities also allow us to manage all erection & installation activities as well as startup of its mechanical, pneumatic & electronic systems managing their Factory acceptance test & Site acceptance test.

Products

Our scope of selection and supply of products for Custody transfer measurement application includes:

- Gas filtering systems

- Gas preheating systems

- Flow metering systems

- Pressure- and/or flow control systems

- Gas distribution filtering/metering/pressure reducing stations

- Electronic metering/station control systems

- Complete Process quality analysis systems

- Supporting steelwork, skids, platforms, stairs and ladders

Key Products

Liquid Measurement Products

A full range of repeatable, reliable and accurate meters & associated instrumentation to cover a wide range of flow rates for liquid measurement with capabilities to offer customs products for special purpose applications.

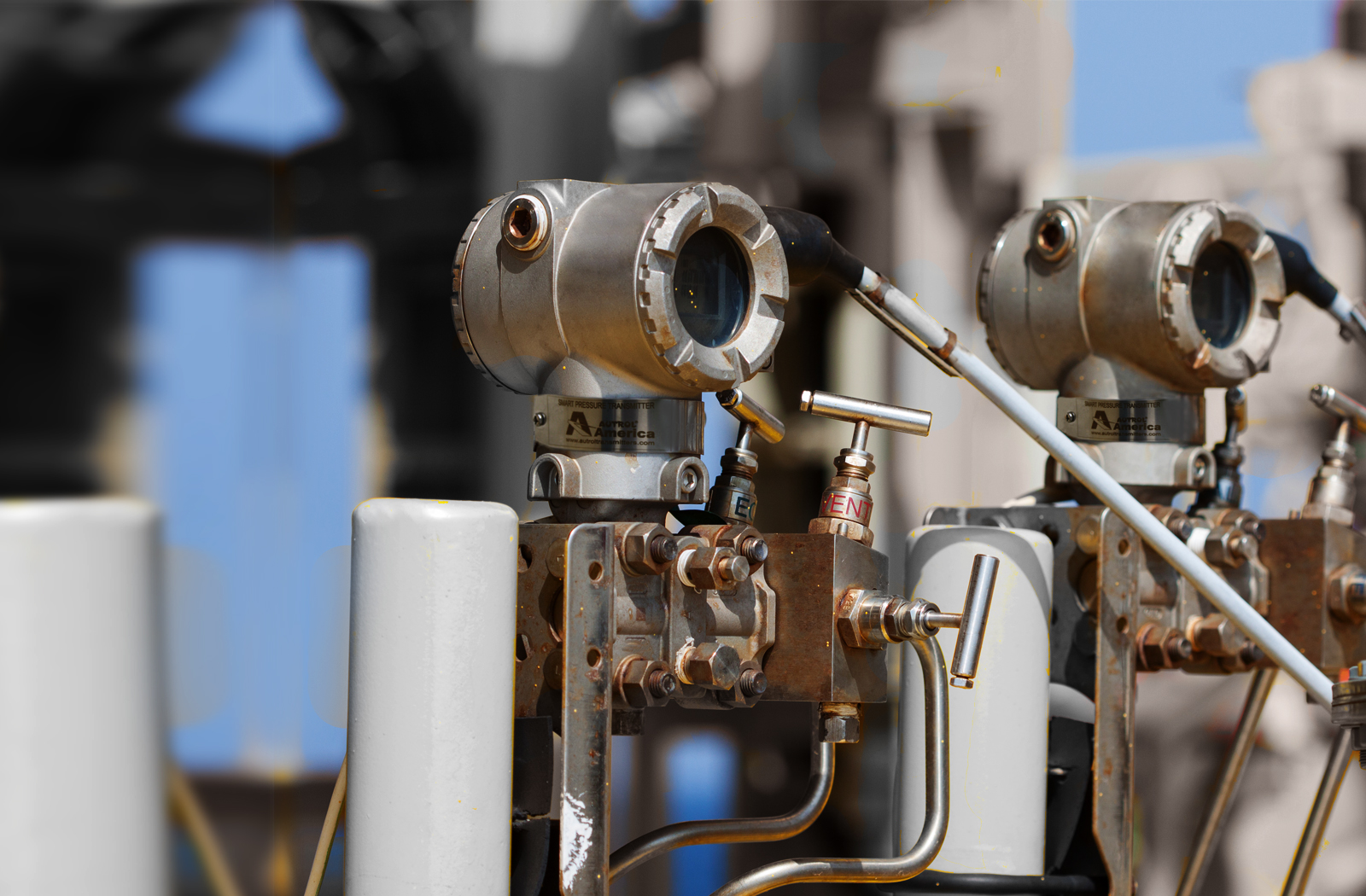

Gas Measurement Products

A full range of repeatable, reliable and accurate meters with full compliance to relevant AGA, API and ISO standards along with associated instrumentation to meet the highest quality, accuracy and performance required for these special purpose applications.

Flow Control Products

Full range of flow control products and systems which can interface to any 3rd party supervisory or SCADA system, and upgrade any legacy system while minimizing CAPEX/OPEX costs.

Process Analyzers

Full range of gas and liquid measurements to support product refinement, process efficiency, and safety. Our Continuous emission monitoring systems meet federal and state laws under EPA and state permitting regulations.

Flow Validation Products

A full range of condition base measurement products for mission critical meter and analyzers to incorporate active redundancy and fault reporting. Our flow validation products use real-time data to prioritize and optimize maintenance resources and help customers minimize spare parts cost, system downtime and time spent on maintenance.

System Integration

As a full service company we offer system integration services of our offered for a code compliant integrated system, designed based on the application and operational requirements further carefully fabricated, assembled, wired and tested. Our systems are not only carefully integrated for long-term accuracy and reliability, but they are also delivered on time to meet our customer schedules.